Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

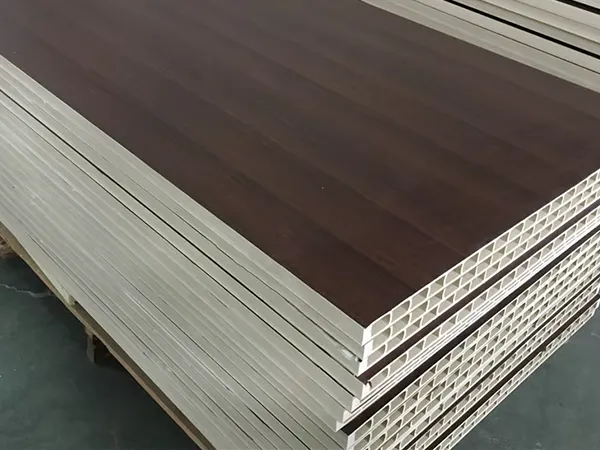

PVC WPC door panel extrusion line typically consists of high-speed mixer, automatic loader, conical twin-screw extruder, mold, vacuum setting table, haul-off unit, cutter, and stacking table.

PVC mixer is mainly used for batching, mixing, coloring, drying of various resins such as polyethylene, polypropylene, polyvinyl chloride, and drying and devolatilization of engineering plastics such as ABS and polycarbonate before molding.

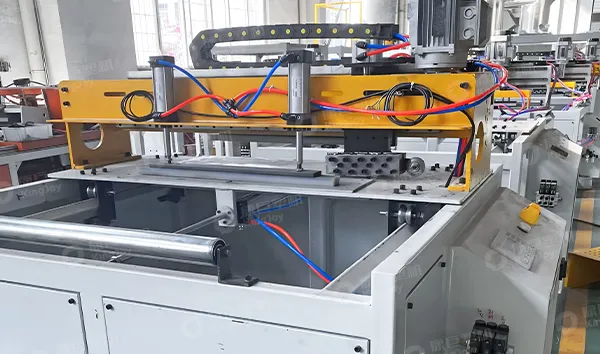

In view of the characteristics of PVC, a conical twin-screw extruder is usually used. It has low shear force, good plasticization, and uniform heat generation, making it very suitable for processing heat-sensitive PVC materials.

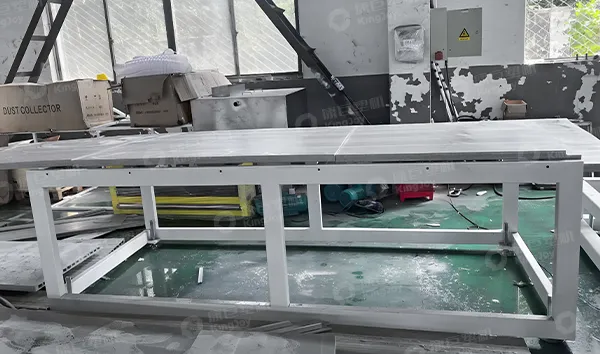

The machine consists of a vacuum setting die and a multi-stage cooling water jacket. The softened profile is firmly attached to the cavity wall of the setting die through vacuum adsorption, achieving precise dimensions and a bright surface.

Provides stable and continuous traction to overcome the resistance of the die head and evenly pull the cooled and hardened profile out of the die. The speed must be synchronized with the extrusion speed, otherwise it will cause material pressing or breaking

The continuously extruded profiles are automatically cut off according to the set length.

Automatically receives cut door panels and stacks them neatly for easy transport and packaging.