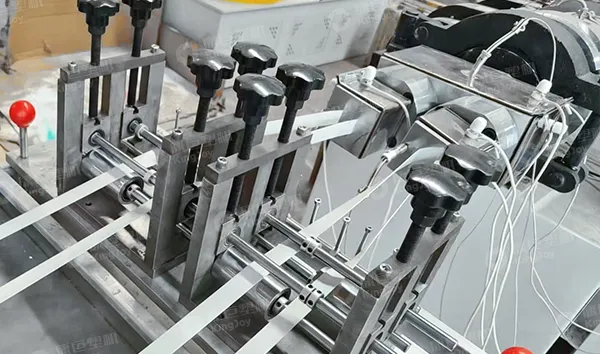

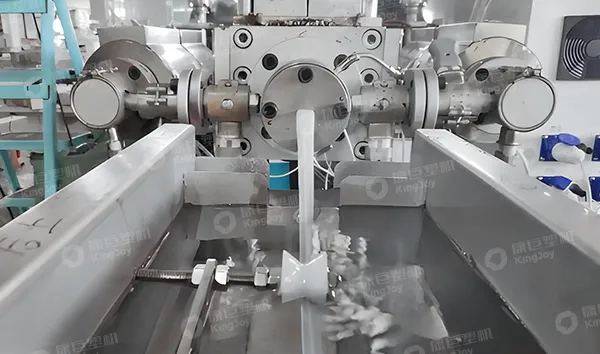

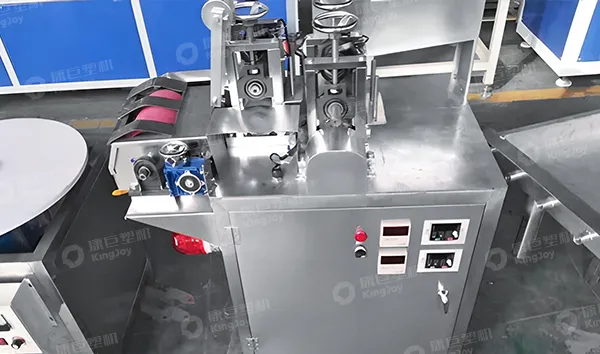

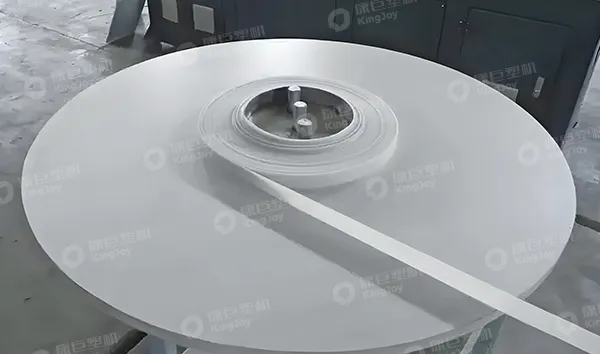

Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.