PVC WPC Foam Board Extrusion Making Machine

PVC WPC foam board extrusion machine is an industrial machine specifically designed for producing polyvinyl chloride (PVC) and wood-plastic composite (WPC) foam boards. The foam board extrusion line combines the core technologies of plastic extrusion, wood-plastic composite and foaming process.

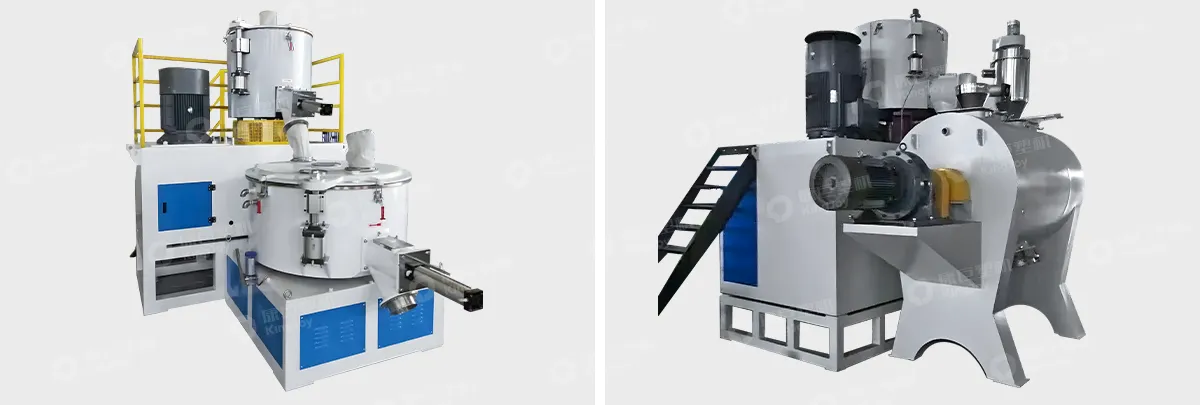

PVC WPC Foam Board Extrusion Line Components:

1. Feeding System: Accurately measures and delivers PVC resin, wood powder, additives, and other raw materials. This typically includes multiple hoppers and metering devices (either loss-in-weight or volumetric).

2. Mixing equipment: such as a high-speed mixer (hot mixer or cold mixer), is used to achieve a preliminary uniform mixing of the raw materials.

3. PVC WPC foam board extruder: use conical twin-screw extruder or parallel twin-screw extruder (more common and more flexible).

4. Extrusion die: This precisely designed, flat, wide die determines the width, thickness, and initial shape of the board. Die design significantly influences foam expansion control, surface quality, and board density distribution.

5. Shaping and cooling device: controls the final thickness and width of the foamed sheet. The sheet surface rapidly cools and hardens, forming a smooth skin (foaming). The expansion rate of the foam is precisely controlled to ensure dimensional stability and flatness.

6. haul-off machine: provides stable and adjustable traction force to pull the cooled and shaped sheet out of the mold at a uniform speed.

7. Cutting/stacking unit: cuts the continuously extruded sheet into desired lengths and automatically stacks them.

PVC WPC Foam Board Production Line Process Types:

1. Free Foaming (Celuka Method): The melt expands freely after leaving the die and then immediately enters the cooling surface of a calibrator or platen, forming a smooth, hard skin with internal foaming. This is the most common method for producing PVC foam boards.

2. Crust Foaming/Co-extrusion Foaming: A dense, unfoamed or slightly foamed skin layer (such as PVC or ASA) is co-extruded over the foam core to provide improved surface hardness, wear resistance, and printability. This typically requires a co-extrusion die and an additional extruder.

WhatsApp: +86-13915693241

WhatsApp: +86-13915693241