Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

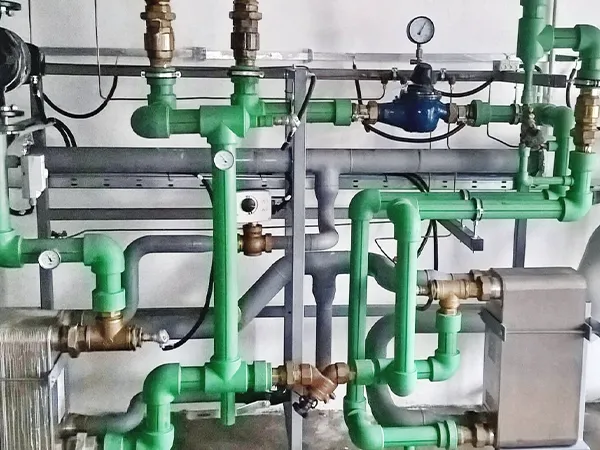

PPR pipe production line is mainly used to produce PPR pipe with diamater from 16 to 630mm. Application fields: hot and cold water systems, heating systems, air conditioning systems, fire protection systems etc.

| Model | Pipe diameter scope (mm) | Extruder model | Production capacity (kg/h) | Installed power (kw) | Line length (m) |

| PP-R-63 | 20-63 | SJ65, SJ25 | 120 | 94 | 32 |

| PP-R-110 | 20-110 | SJ75, SJ25 | 160 | 175 | 38 |

| PP-R-160 | 50-160 | SJ90, SJ25 | 230 | 215 | 40 |

| PE-RT-32 | 16-32 | SJ65 | 100 | 75 | 28 |