Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

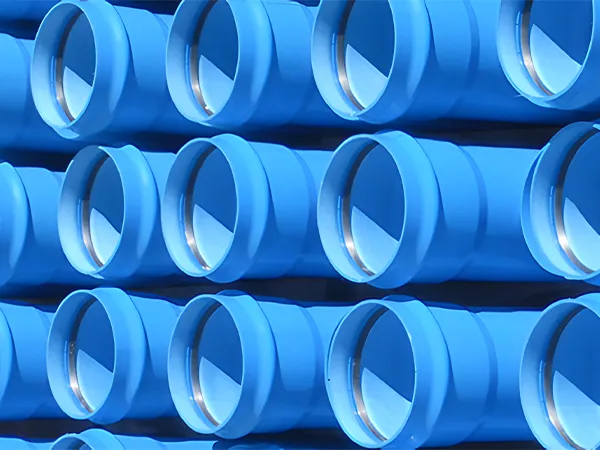

The global demand for high-performance piping solutions has driven significant advancements in PVC-O (Biaxially Oriented PVC) pipe extrusion technology, a cutting-edge manufacturing process that enhances pipe strength, longevity, and environmental efficiency. PVC-O pipes, produced through specialized bidirectional stretching techniques, are revolutionizing applications in water supply, gas distribution, and industrial systems worldwide.

| Pipe Range | Extruder | Haul-off Speed | Capacity |

| 90-250mm | SJSZ65 | 1.5-8m/min | 300kg/h |

| 110-315mm | SJSZ75 | 0.5-5m/min | 500kg/h |

| 400-630mm | SJSZ92 | 0.1-2m/min | 800kg/h |

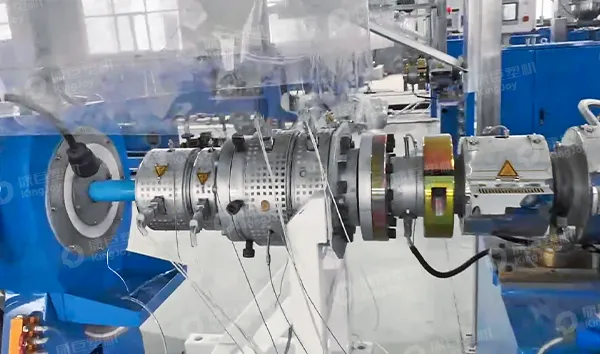

PVC-O pipe extrusion machine adopts the optimized longer L/C ratio screw, applied on PVC and formulation materialextrusion, has advantages on low wearing, low energy consumption, high efficiency, uniform and stable extrusion.

Extrusion die head apply spiral structure, each material flow channel is placed evenly. Each channel is after heat treatment and mirror polishing to ensure material flow smoothly.