Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

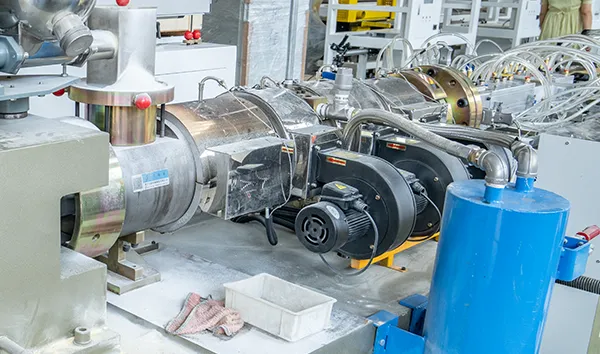

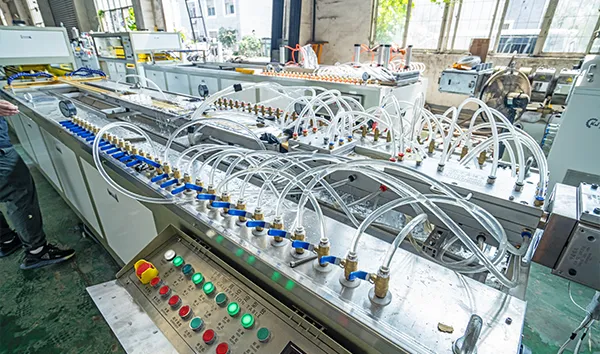

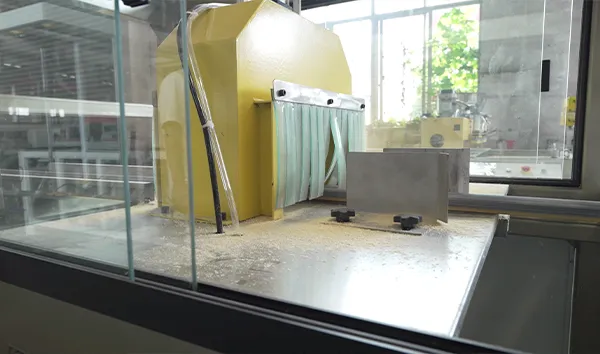

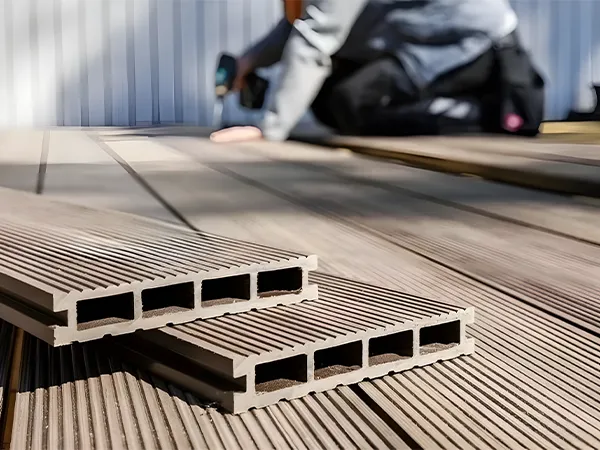

PE PP wood plastic profile production line is designed for the manufacturing of wall panel, window panels, ceiling panel, outdoor landscape, fence, pergola, decking, gratings, sauna board, poles,etc. PE PP wood plastic profile extrusion line includes several key components: control system, conical twin-screw extruder or parallel twin-screw extruder, calibration unit, haul-off unit, cutter, film covering machine, and stacker.

| Extruder model | Extrude output | Main motor power | Screw speed | Cooling outside the barrel |

| SJZS 51/105 | 100-150kg/hour | 18.5kw; AC motor | 38.4 rpm | 400w × 3 wind cooling fan |

| SJZS 55/110 | 180-280kg/h | 22 kW; AC motor | 38.4 rpm | 400w × 3 wind cooling fan |

| SJZS 65/132 | 300-350 kg/h | 37 kW; AC motor | 38.4 rpm | 550w × 3-wind cooling fan |

| SJZS 80/156 | 400-450kg/h | 75 kW; AC motor | 40 rpm | 550w × 5 wind cooling fan |