Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

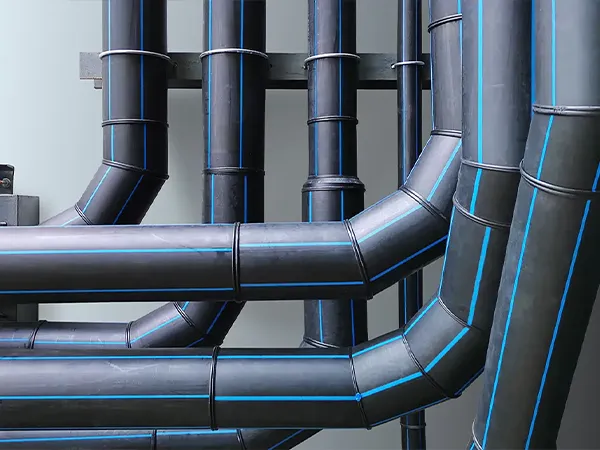

PE pipe production line is mainly used to produce PE pipe with diamater from 16 to 1600mm. Application HDPE pipes, LDPE pipes, PE pipes, water supply pipes, gas supply pipes, irrigation pipes, sewer water pipes making.

| Model | extruder | Pipe range(mm) | Capacity (kg/hour) | Main motor power (kW) | Total power (kW) | Line length (meters) |

| PE-63 | SJ65/33 | 16-63 | 120-180 | 45 | 110 | 28 |

| PE-110 | SJ65/33 | 16-110 | 150-200 | 55 | 130 | 28 |

| PE-160 | SJ75/33 | 150-160 | 180-220 | 75 | 150 | 30 |

| PE-250 | SJ75/33 | 75-250 | 280-350 | 90 | 280 | 30 |

| PE-315 | SJ90/33 | 110-315 | 300-400 | 132 | 350 | 36 |

| PE-450 | SJ90/33 | 160-450 | 350-450 | 160 | 400 | 42 |

| PE-630 | SJ120/33 | 315-630 | 550-850 | 200 | 550 | 45 |

| PE-800 | SJ150/33 | 450-800 | 800-1200 | 250 | 650 | 45 |

| PE-1200 | SJ120/33 90/33 | 710-1200 | 1000-1500 | 285 | 800 | 48 |

| PE-1600 | SJ120/33 120/33 | 800-1600 | 2000-3000 | 500 | 1200 | 48 |