Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

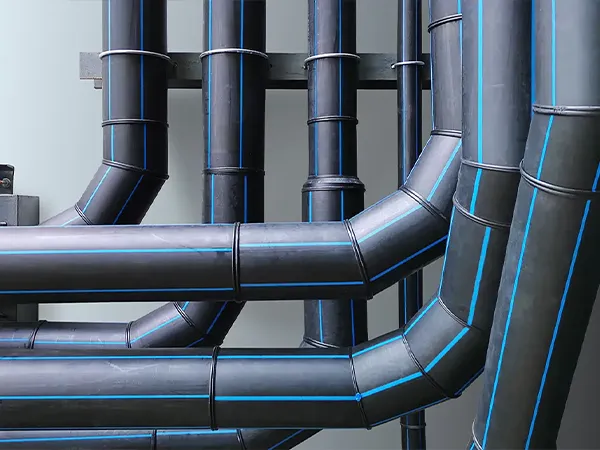

PE pipe extrusion line is designed for high-output production of HDPE, MDPE, and LDPE pipes for a wide range of applications – from potable water and gas distribution to industrial and sewer systems.

PE pipe extrusion line is designed for high-output production of HDPE, MDPE, and LDPE pipes for a wide range of applications – from potable water and gas distribution to industrial and sewer systems. The complete PE pipe production line turnkey solution is designed to maximize your productivity and ROI while ensuring consistent, top-tier product quality.

1. At the heart of the PE pipe production line is our advanced single-screw extruder. Featuring a robust DC drive, optimized screw and barrel design for superior plasticization, and precise temperature control systems, it ensures stable extrusion, exceptional melt homogeneity, and maximum throughput with minimal energy consumption.

2. Our custom-engineered spiral die heads guarantee uniform wall thickness distribution and optimal melt flow, eliminating weld lines. This is critical for producing pipes with outstanding concentricity and long-term hydrostatic strength.

3. The precision calibration tank utilizes a vacuum sizing system to accurately set the pipe’s outer diameter and wall dimensions immediately after extrusion. Advanced water level and temperature control ensure smooth, stable pipe formation and perfect surface finish.

4. A long, multi-section cooling tank provides gradual and thorough cooling of the pipe. This prevents internal stresses and deformation, ensuring the geometric stability and mechanical properties of the finished product.

5. The heavy-duty caterpillar haul-off unit provides continuous, synchronized, and slip-free traction. Its precise speed control is crucial for maintaining consistent pipe dimensions and a smooth production process.

6. An automatic planetary cutter (orbital cutter) delivers clean, burr-free cuts with absolute perpendicularity for pipes of various diameters.

7.The PE pipe extrusion line can be configured with an automatic coiler for small to medium-diameter pipes or a stacker for large-diameter pipes, facilitating efficient handling, storage, and logistics.

| Model | extruder | Pipe range(mm) | Capacity (kg/hour) | Main motor power (kW) | Total power (kW) | Line length (meters) |

| PE-63 | SJ65/33 | 16-63 | 120-180 | 45 | 110 | 28 |

| PE-110 | SJ65/33 | 16-110 | 150-200 | 55 | 130 | 28 |

| PE-160 | SJ75/33 | 150-160 | 180-220 | 75 | 150 | 30 |

| PE-250 | SJ75/33 | 75-250 | 280-350 | 90 | 280 | 30 |

| PE-315 | SJ90/33 | 110-315 | 300-400 | 132 | 350 | 36 |

| PE-450 | SJ90/33 | 160-450 | 350-450 | 160 | 400 | 42 |

| PE-630 | SJ120/33 | 315-630 | 550-850 | 200 | 550 | 45 |

| PE-800 | SJ150/33 | 450-800 | 800-1200 | 250 | 650 | 45 |

| PE-1200 | SJ120/33 90/33 | 710-1200 | 1000-1500 | 285 | 800 | 48 |

| PE-1600 | SJ120/33 120/33 | 800-1600 | 2000-3000 | 500 | 1200 | 48 |