Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

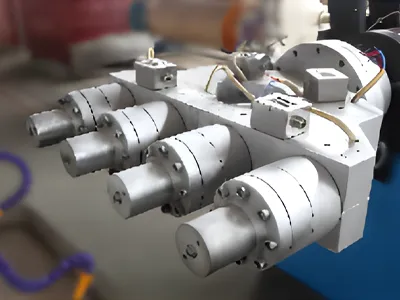

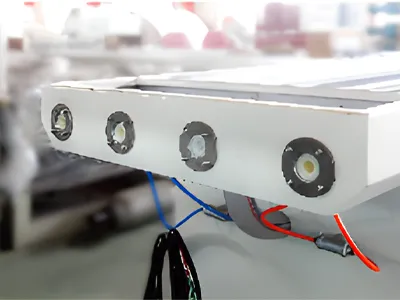

PVC four cavities pipe production line is composed of conical twin-screw extruder 65mm, 4 cavity mould, 4 cavity coling calibration tank, 4 station haul off, 4 station cutter and 4 station tipping table.

PVC four cavities pipe production line can extruder four pipes at same time on one machine. This PVC pipe extrusion line can save investment cost in factory buiding and production, which increase the capacity a lot and reduce production time. SJSZ65 conical twin-screw extruder can easily reach 5.5-6.5 ton/per day,the production speed take 16mm as example can get more than 8-10m/min.

PVC four cavities pipe production line is composed of conical twin-screw extruder 65mm, 4 cavity mould, 4 cavity coling calibration tank, 4 station haul off, 4 station cutter and 4 station tipping table.

PVC pipe extrusion line adopt advanced technology from twin conical screw extruder to the down-stream line of four-outlet stainless steel vacuum calibration tank and spray cooling tank. This design will avoided the energy and materail waste phenomenon cause of the pipes adjustment when pipe on production. And the technology of four haul-of unit and cutter have been fused together very wel with the four outlet vacuum calibration tank and spray cooling tankthey can be automatic independent and flexible control to reduce the defective index of fiished products, so as to improve the production efficiency and help customers make more benefit from the new technology.

1. Ensuring long-time stable operation & long service life

2. PVC pipe extrusion machine has compact structure, low noise, high bearing capacity, high transmission efficiency, ensuring long-time stable operation

3. Heating is controlled by Solid State Relay (S.S.R), realizing stable heating; (SSR) no spark & no noise improve safe production.

4. Siemens PLC controlling system with reliable technology, automatic and intelligent functions for centralized control and monitoring extrusion lines, which helps easy operation.

| Diameter | 16-40 | 20-63 | 50-160 | 75-250 | 110-315 | 160-450 | 315-630 |

| Diameter of screw | 51/105 | 65/132 | 65/132 | 80/156 | 80/156 | 92/188 | 92/188 |

| Main power | 18.5 | 37 | 37 | 55 | 55 | 110 | 110 |

| Heating zone | 13KW*4 | 28KW*4 | 28KW*4 | 39KW*4 | 39KW*4 | 45KW*4 | 45KW*4 |

| Vacuum power | 2.2KW*2 | 2.2KW*2 | 2.2KW*2 | 3KW*2 | 4KW*2 | 4KW*2 | 5.5KW*2 |

| Capacity | 100-120 | 150-200 | 180-250 | 250-350 | 300-400 | 500-600 | 600-700 |