Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

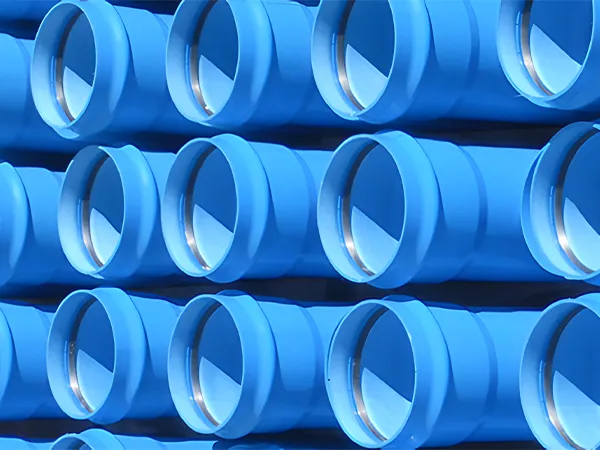

PVC pipe production line is mainly used to produce PVC pipe with diamater from 16 to 800mm. Kangju Machinery have different kinds of PVC pipe extrusion line to produce different kinds of PVC pipes: UPVC pipe, CPVC pipe, PVC-O pipe, PVC-M pipe, etc. PVC pipes we produce are used in different industries, such as: urban water supply and drainage, industrial sewage systems, agriculture, construction, power and telecommunications industries, etc.

PVC pipe extrusion line is composed of PVC mixer, conical twin screw extruder, vacuum calibration tank, haul off, motors, cutter, belling machine and stacker etc.

| Mode | Pipe Range(mm) | Extruders | Max. Output (kg/h) | Max. Speed (m/min) | Total Power (kw) |

| PVC-50x2 | 16-50 | SJSZ51/105 | 150 | 6m | 60w |

| PVC-63 | 16-63 | SJSZ45/90 | 120 | 10m | 45w |

| PVC-110 | 50-110 | SJSZ51/105 | 150 | 6m | 60w |

| PVC-160 | 63-160 | SJSZ65/132 | 300 | 5m | 100w |

| PVC-250 | 110-250 | SJSZ80/156 | 400 | 3.5m | 120w |

| PVC-315 | 160-315 | SJSZ80/156 | 400 | 3m | 160w |

| PVC-450 | 250-450 | SJSZ92/188 | 700 | 1.5m | 200w |

| PVC-630 | 315-630 | SJSZ92/188 | 700 | 0.9 | 230kw |

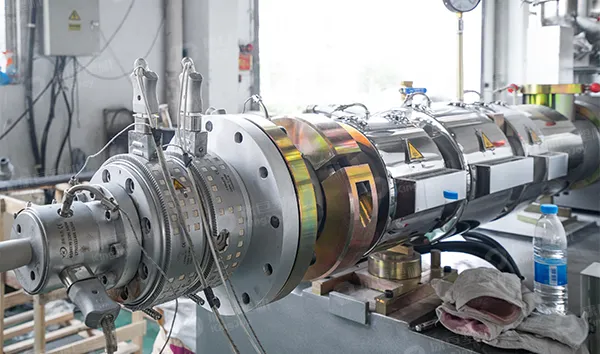

PVC pipe extrusion machine adopts the optimized longer L/C ratio screw, applied on PVC and formulation materialextrusion, has advantages on low wearing, low energy consumption, high efficiency, uniform and stable extrusion.

Extrusion die head apply spiral structure, each material flow channel is placed evenly. Each channel is after heat treatment and mirror polishing to ensure material flow smoothly.