Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

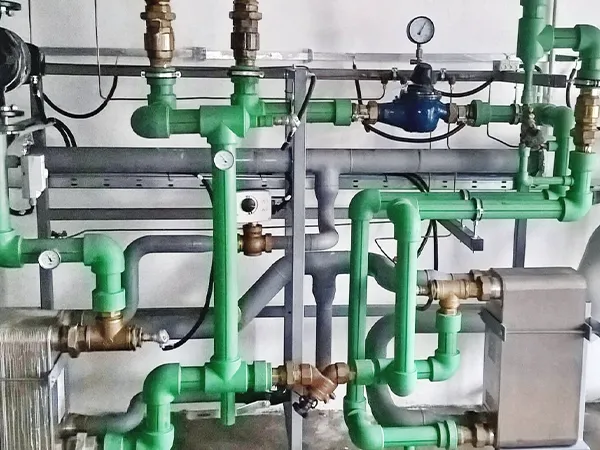

PPR hot cold water pipe extrusion line is used to produce PPR pipes for cold and hot water supply in house.

PPR hot cold water pipe extrusion line is used to produce PPR pipes for cold and hot water supply in house. PPR water pipe extrusion line consisted of vacuum feeding machine, hopper dryer, single screw extruder, mould, mark line co-extruder, vacuum calibration and cooling tank, extended spraying cooling tank, haul off machine, printer, cutter and stack bracket.

And for three layers PPR fiber reinforced pipe, there will be also another extruder for middle fiber layer. PP-R pipe can be single layer with mark line extruded by one extruder, or two layers, or three layers with middle layer glass fiber reinforced extruded by two or three high efficiency extruders; or four layers ppr glass fiber reinforced pipe, etc.

1. Linear expansion co-efficient is only about 20-30% compared to normal PPR products, completely solve the problem of plastic pipe stretching.

2. The PPR pipes produced by the PPR water pipe production line have rigidity of the pipe to prevent the pipe sagging, while also reducing the density and number of fixed support points, thereby reducing the overall cost of the project.

3. Higher pressure levels, longer life under normal design tremor force.

4. High temperature performance is better, save energy, FR / PP-R apply in hot water systems, the normal temperature up to 95-100℃, both to improve the use of the medium temperature, but also reduce the thickness of insulation material. Comprehensive cost is less.

5. Large water flow: at the same level of pressure conditions, thickness of the FR / PP-R pipe wall increases the inner diameter of the pipe thereby increasing the water flow rate (20%)

6. Solve the problem of the oxygen permeability of the pipeline, direct contact with the water table within the health is non-toxic, sealing, and will not form sphagnum moss.

| Model | Pipe diameter scope (mm) | Extruder model | Production capacity (kg/h) | Installed power (kw) | Line length (m) |

| PP-R-63 | 20-63 | SJ65, SJ25 | 120 | 94 | 32 |

| PP-R-110 | 20-110 | SJ75, SJ25 | 160 | 175 | 38 |

| PP-R-160 | 50-160 | SJ90, SJ25 | 230 | 215 | 40 |

| PE-RT-32 | 16-32 | SJ65 | 100 | 75 | 28 |

PPR Plastic Pipe Extrusion Line Video

PPR Cold Hot Water Pipe Production Line Video