Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

Kangju Machine specializes in manufacturing high-quality plastic extrusion equipments. Including plastic pipe extrusion line, plastic sheet production line, plastic profile extrusion line, plastic plate extrusion line.

PPR pipe extrusion making machine is mainly composed of control system, extruder, die head, vacuum calibration unit and haul-off and cutting units, printer and stacker and pipe collector.

PPR pipe extrusion making machine is mainly composed of control system, extruder, die head, vacuum calibration unit and haul-off and cutting units, printer and stacker and pipe collector. The die head adopt lattice or spiral mould and can suit for the static mix system. Special vacuum calibration unit and spray cooling system: two section vacuum calibration unit, perfect water temperature, water lever and flow rate control to guarantee the pipe products with high quality.

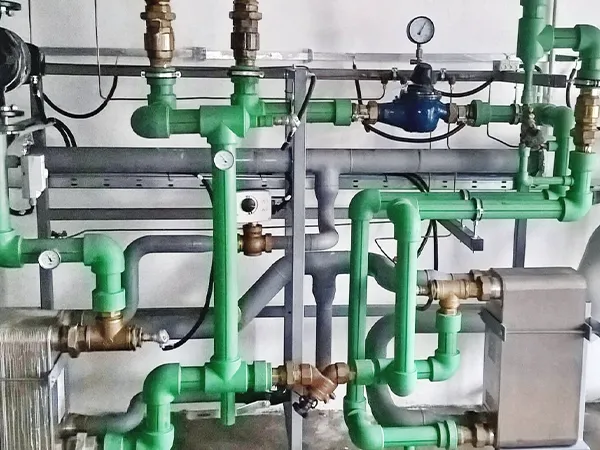

PPR pipe extrusion line is widely used in hot and cold water piping system, air conditioning system and so on. PPR pipes has the advantages of health, non-toxic, recyclable, high wear resistance, strong corrosion resistance, good sound insulation performance and long service life.

In the production process, PPR pipe extrusion line use efficient single-screw extrusion technology to ensure good plasticizing effect and production stability. In addition, modern PPR pipe making machine is equipped with advanced control systems, making the operation easier and easy to maintain.

| Model | Pipe diameter scope (mm) | Extruder model | Production capacity (kg/h) | Installed power (kw) | Line length (m) |

| PP-R-63 | 20-63 | SJ65, SJ25 | 120 | 94 | 32 |

| PP-R-110 | 20-110 | SJ75, SJ25 | 160 | 175 | 38 |

| PP-R-160 | 50-160 | SJ90, SJ25 | 230 | 215 | 40 |

| PE-RT-32 | 16-32 | SJ65 | 100 | 75 | 28 |

PPR Plastic Pipe Extrusion Line Video

PPR Cold Hot Water Pipe Production Line Video